Copyright © Dongguan GiPin Plastic And Cast lron Co., Ltd. All Rights Reserved. Site Map

- +86-13602337865

- jason_gipin@outlook.com

- No. 6, Beimen 1st Road, Nankeng Village, Qishi Town, Dongguan City, Guangdong Province

- Home

-

Our Services

- Die-Cast Aluminum Alloy Audio Products

- Die-Casting Aluminum Alloy Communication Products

- Aluminum Alloy CNC Processing Products

- Die-Cast Zinc Alloy Automotive Communication Products

- Die-Cast Zinc Alloy 3C Electronic Products

- Aluminum Alloy Die-Casting Molds, Zinc Alloy Die-Casting Molds, CNC Machining Fixtures, Stamping Molds, Plastic Molds

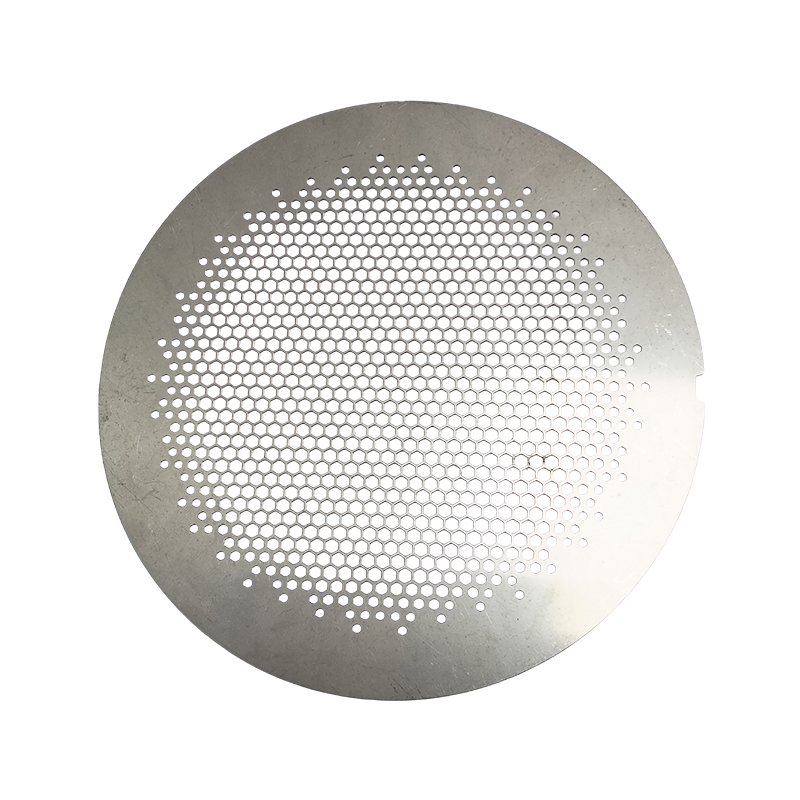

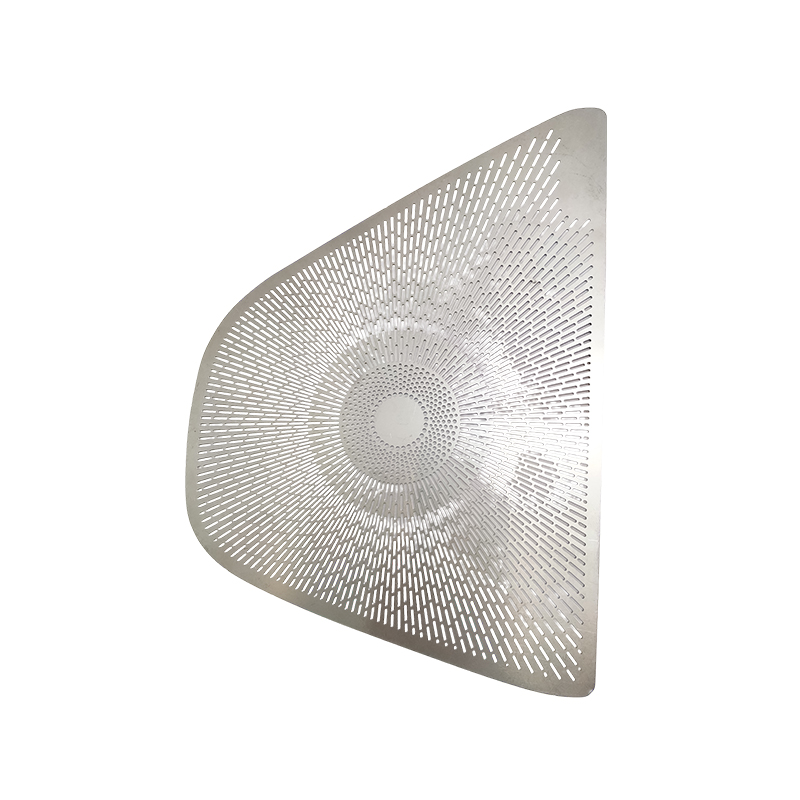

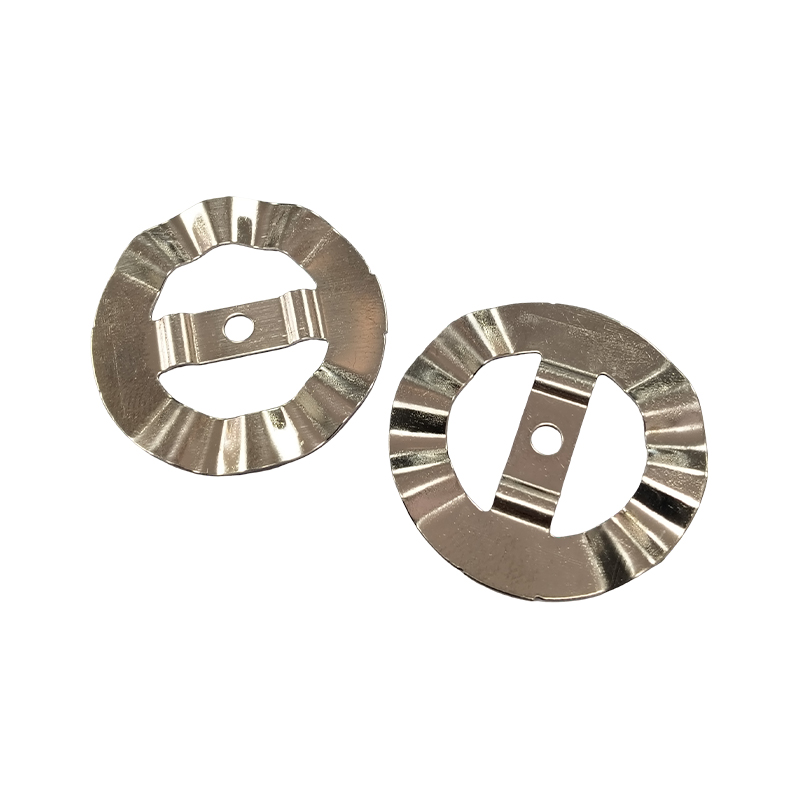

- Stamping Parts

- Display

- Solutions

- News

- About

- Partners